October 2021

Manfred Snijders extra yield and food process technologist joins Symotab to provide his extensive experience to our European food industry. Europe is first with Manfred!

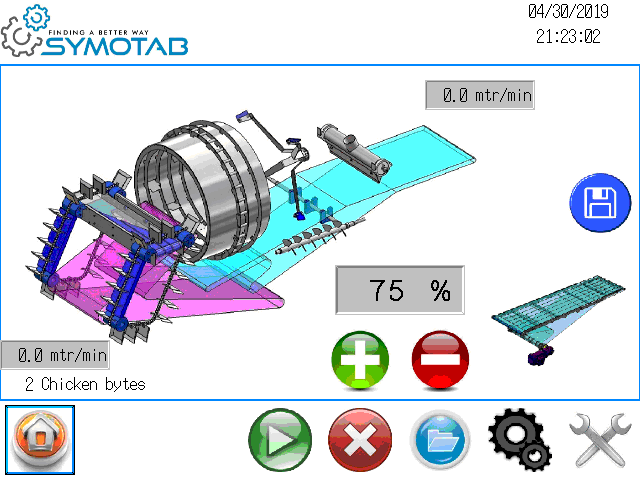

On Valentines day 2017, Symotab introduced CombiCoater, a new from the ground up designed coating machine for flour and crumb

Why on Valentines day? Because CombiCoater is constructed with love for customers, love for operators and love for maintenance personnel.

Let’s look at these claims in more detail:

Love for customers:

Imagine a 250 mm wide curtain of breadcrumb or pre-dust lusciously covering your products from all sides. A precision air-knife finishes the job by removing excess coating material assisting towards cleaner frying oil in the next step.

One production machine that can be converted from flat bed breading to drum breading saves valuable production space as less different machines are needed.

The design is beautiful with clean-ability and hygiene as top priority. No hidden places that are hard to clean on Combo Coater. A great looker looking good in any production line.

Love for operators:

A beautiful color touchscreen with icons for each one of the 9 frequency driven motors makes adjustments a breeze.

Feed back if a door is not closed pointing it coloring blue. Emergency stop was pressed, which one? There are 4 of them, Touchscreen shows which one of them is blinking. Change over from drum to flat bed in just a few clicks, no tools needed, can be done in 3 minutes flat

Completely recipe driven whereby the menu tells if the drum should be in place or not

Bulk loader available for up to 160 kg of coating material without the need to lift bags higher than 80 cm from the floor.

Love for maintenance personnel:

Just open the doors every once in a while to see why Combo Coater keeps on running and doing it’s job in silence. See the motor mounts with reactive arms offering stable drives. Top of the line SEW electric motors and gearboxes ensure world wide availability and after sales service.

Naturally the complete European design is metric and parts are standard available around the corner. The clear touchscreen has fault memory too. Operators will not ask for help much either as the touchscreen is so easy to understand and logic and language free, it’s a breeze!

I want to thank the team of engineers and production personnel of VDL Systems in Uden. You have shown great team spirit and love for detail which our customers will see back in the truly great Combo Coater that you created. I found in you the pride of workmanship that shows in the precision welding, how well all materials fit together and the softness of all edges that helps in a work safe environment. Thank you VDL Systems Uden Netherlands!

Ad Bontje,

Ad@symotab.com